- Home

- Production Machines of Insulators

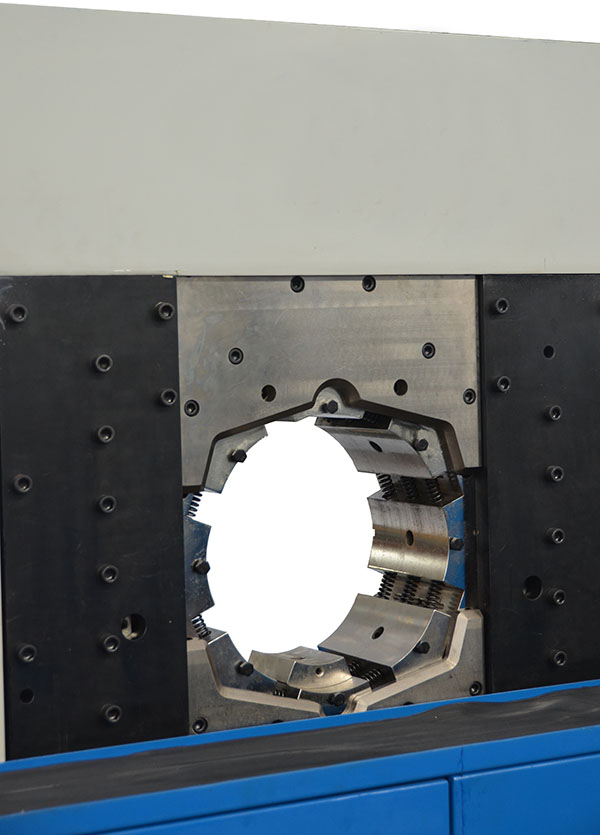

- CRIMPING MACHINE 165 FOR COMPOSITE INSULATOR PRODUCTION

CRIMPING MACHINE 165 FOR COMPOSITE INSULATOR PRODUCTION

The crimping machine is applied in the production line of high voltage composite insulator (polymer insulator) to crimping metallic end fittings to FRP of the insulator. Model 165 is available for an insulator with voltage up to 800KV

- General Details

- Technical Info

- Comments

- Related Products

What is a crimping machine/crimper?

The crimping machine is used to crimp the metal fittings of high voltage insulators during the insulation production process, it is a vital and essential production machine of composite insulators (silicone rubber insulators).

Why didn’t I find enough crimping machines in Google search?

Some new manufacturers like to search the Internet for “Fitting pressing machine” to start their new composite insulator factory, but in fact, we call it a crimping machine, in Chinese “压接机” which is more common and professional.

How does a crimping machine work?

With high hydraulic pressure, the crimping machine presses the metal fitting in all directions and makes the metal fittings securely attached to the fiberglass rod of the composite insulators.

How does a crimping machine help a manufacturer of insulators?

This crimping machine is necessary for the manufacturing of composite insulators, which is also known as “silicon rubber insulator” or “polymeric insulator”. With this crimping machine 165, the composite insulator of different types, including pin type polymeric insulator, post type polymeric insulator, suspension polymeric insulator, tension polymeric insulator (long rod insulator) can be crimped with this machine, voltage of which can be from 11KV up to 800KV.

What are the advantages of crimping machines supplied by Contune Intl compared to other’s crimper?

- Modern design philosophy

Designed with the “Soft crimping” theory, it has a function of slow crimping and pressure holding function and it’s capable to set pressure by different sections, which assures best-crimping quality. This function is owned by Contune Intl and its collaborating factory only, the effect of which is particularly obvious on insulator of high mechanical load. - Double control to achieve the best crimping quality

Both crimping quantity and crimping force are used to control crimping quality. So under the same condition, this machine can achieve a crimping effect with maximum tensile load and minimum discreteness, which largely solves the bad effect caused by the different hardness of ball and socket fitting, improves the effect of crimping. - Higher speed, higher efficiency

With special optimization by Contune Intl, this machine is faster than the average product from other suppliers, enabling the manufacturer to have higher efficiency in their production.

Compared with crimping machine model 140, this model 165 has a bigger opening diameter, bigger pressing force of crimping and more advanced function like cantilever-arm screen, which makes it enable to suit bigger post insulator with higher voltage level, greater cantilever strength, bigger diameter of fiberglass core and bigger flange base. To be more advanced, a sound detective system is an optional configuration for the user to check the crimping quality of fitting, which named “acoustic emission system”. With this AES, the user will be able to judge whether there are cracks in FRP/ECR rods during the crimping process. The curve on the screen will indicate a sudden crack of structure and help the user to observe and make the judgement of FRP rods status.

For a lower-level voltage of insulator and lower price, please refer to another type “crimping machine 140” by clicking the “Related products” label above.

| Name | Crimping machine |

| Model. | CTCPM-165 |

| Manufacturer | Contune Intl Co.,Ltd |

| Max crimping diameter | 250mm |

| Diameter difference between min opening and max opening | 150mm |

| Crimping range | Diameter 6.8mm to 250mm |

| Length of min crimping module | 116mm |

| Pressing force | 6000kN |

| Control mode | PLC |

| Power consumption | 7.5kW |

| Power supply | 380V , 50Hz |

| Weight of crimping device | About 6000 kgs |